…are our best references:

- Chemical cleaning Quenching Column C1503, C1501 and Choppers Primary

- Chemical cleaning side H2O (internal tubes) of the plant P1CR Furnaces (Cracking) on behalf of Refinery Versalis SpA of Brindisi, operation performed (washing chemical pre branch – Acid Wash – neutralization branch post passivation)

- Chemical Cleaning Column Vacuum – Vacuum Wax – etc, on behalf of the Refinery Agip/ ENI in Livorno

- Chemical Cleaning Column Vacuum – Topping – Mea – Reforming, etc.., on behalf of the Refinery SARPOM SpA S. Martino of Trecate (NO)

- Chemical Cleaning Column Vacuum – Merox – Vis-Breaker – Alkylation – etc., on behalf of Refinery Oils ENI Sannazzaro de ‘Burgondi (PV)

- Chemical Cleaning Column Topping – Vacuum etc. .. on behalf of the Refinery IPLOM SpA – Busalla (Genoa)

- Chemical cleaning Columns Sector Benzene – Ethylbenzene – Ofethylbenzene on behalf of Refinery Versalis SpA in Mantova

- Chemical Cleaning hydrofluoric acid alkylation Section – ex-refinery IP Rho (MI)

- Chemical Cleaning hydrofluoric acid alkylation Section – Refinery Agip/ENI Sannazzaro de Burgondi (PV)

- Chemical Cleaning Alkylation Section – on behalf of Refinery Versalis SpA in Mantova

- Chemical cleaning convection and radiant section of Refinery furnaces in normal running conditions:

This type of operation can be performed with three different methods:

• dry chemical cleaning of radiant and convection section;

- dry and wet chemical cleaning (dry radiant and convection part) wet (usually

the upper of convection);

- only wet chemical cleaning (this type of intervention concerned only the convection

area).

- Cold chemical cleaning fumes side radiant and convection furnaces of Refinery

- Cold chemical cleaning fume side of Boilers

- Chemical cleaning pickling + passivation side water of boilers

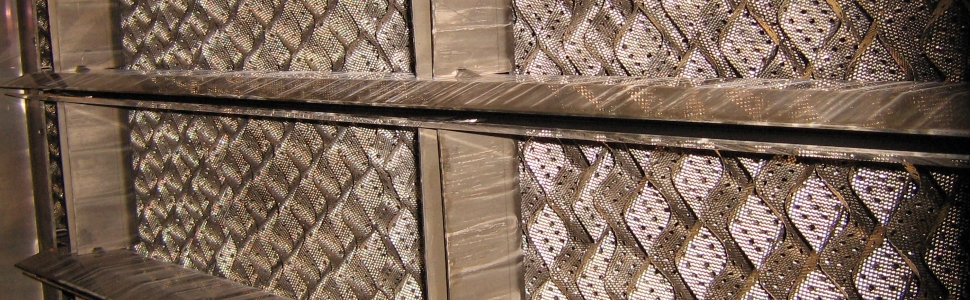

- Chemical cleaning heat exchanger PACKINOX

- Chemical cleaning and drainage tanks and Sulphuric Acid Area : We have performed the complete decommissioning of plants (sulphuric acid) on behalf of Refinery IP Rho

- Chemical cleaning of Lines Compressors – type of intervention:

chemical alkaline cleaning acid neutralization and passivation Lines suction Compressor suction (pre- commissioning )- Chemical cleaning austenitic steel and not

- Chemical cleaning of condenser and refrigerator oil

- Chemical cleaning of coil Refinery and circuits reaction

- Chemical cleaning exchangers and plate heat exchangers

- Chemical cleaning alkaline- acid – of Air Coolers , process side

- Chemical cleaning external fins on the air side – Air Coolers

- Chemical cleaning baskets Lyungstrom

- Chemical cleaning Chimneys

- Chemical cleaning and drainage Vessel Blow-Down

- Chemical cleaning alkaline – acid Lines Blow-Down

- Chemical cleaning alkaline- acid Lines Fuel Gas burners of furnaces

- Chemical cleaning alkaline degreasing lines fuel oil burners of furnaces

- Chemical cleaning exchangers water and process side

- Chemical clearing of Electro filter

- Chemical cleaning alkaline amines circuit – Unit 31 / Gasification Plant – SNAMPROGETTI SpA on behalf of ENI SpA – Sannazzaro of Burgondi (PV)

- Chemical cleaning alkaline – acid – passivation lines gas in carbon steel Compressor J-33001 A / B – COMECF on behalf of Snamprogetti SpA – Refinery ENI SpA – Sannazzaro of Burgondi (PV)

- Chemical cleaning degreasing Circuits amines Section ISOCRACKER and associated units – on behalf of SNAMPROGETTI SpA / Saipem SpA – ENI SpA R & M Refinery Sannazzaro de Burgondi (PV)

- Chemical cleaning, passivation of suction Circuits J3482A/B/C J3481 Section ISOCRACKER – SNAMPROGETTI SpA / Saipem SpA – ENI SpA Refinery – R&M Sannazzaro de Burgondi (PV)

- Chemical cleaning alkaline (degreasing) of Circuit Amine System 33 – Section DEASPHALTING – on behalf of Saipem SpA – Eni SpA Refinery Sannazzaro de Burgondi (PV)

- Chemical cleaning alkaline (degreasing) new Section Amines Sulphur 4 – line 6 “Interconnecting to limit battery Hydrocracking- on behalf of SNAMPROGETTI SpA – Refinery ENI R & M Sannazzaro de Burgondi (PV).

and many others..